Long Island City Machinist Shop Crew ‘Keep NYCHA Going’

When an elevator breaks down at one of NYCHA’s developments, requiring a traction pulley or bearing to be repaired, NYCHA’s machinist shop in Long Island City will likely get the call.

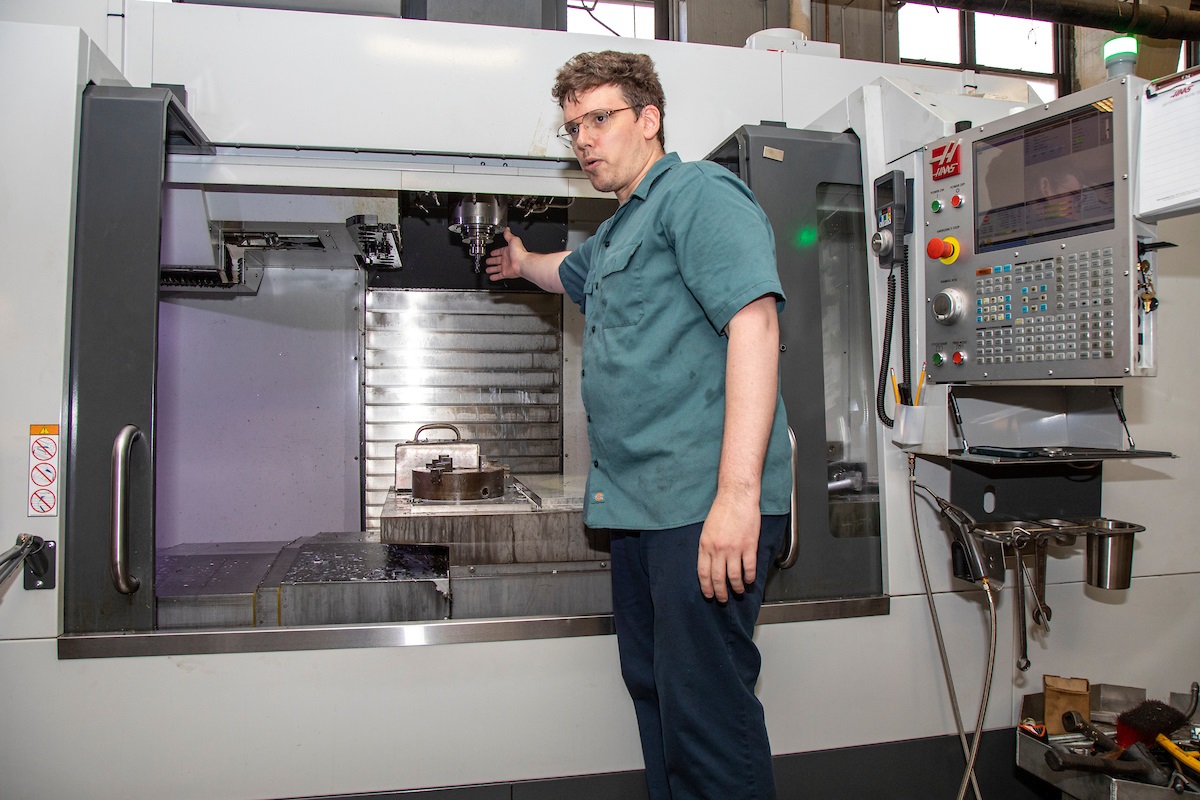

In the basement of one of NYCHA’s satellite offices, the shop houses specialized machinery such as a CNC (computer numerical control) lathe and vertical lathe, which are designed to recondition or resurface elevator and heating system parts that wear down over time. It is often how NYCHA gets elevator or heating and hot water service back up and running in a timely manner for residents: Various parts that are in rare supply, aging, or too costly to replace can be reconditioned on-site.

Standing beside the CNC lathe machine – which looks like a hyperbaric chamber – NYCHA machinist Dan Schell said regarding the machine’s efficiency, “It’s the way to do it.” The machine is controlled by a computer program that gives design instructions to drill holes for parts or perform other technical functions with precise specifications.

While the shop’s three staff machinists regularly work on component pieces sent over from the Elevator Services & Repair Department, the shop also handles requests for part fixes from various departments and crews across NYCHA, including heating and plumbing, as well as for miscellaneous services. In certain cases, the shop can even use the machines to make tools for touching up the different components.

“We’re at the disposal of NYCHA,” said Mr. Schell, who has worked as a machinist for about 16 years.

Fellow machinist Anthony Dombroski, who has decades of experience with machinery, added, “We’re virtually anybody at NYCHA’s shop when they need it.”

Noting how the machinist crew is ready to assist with reconditioning parts for critical elevator and heating and hot water services, Technical Services Department Administrator Colin Lowe simply said, “These guys keep NYCHA going.”

In addition to Mr. Schell and Mr. Dombroski, the shop team includes machinist Zamal Kahn, as well as supervisors and Resident Buildings Superintendents Vincent Giocastro and Domenic Ospedale. Repair orders may come in at all times of the day, and the crewmembers have sometimes needed to work through the night to help ensure that elevator services can return promptly.

“We take pride in what we do, and working on the equipment to get it ready so we can have it back in service for the residents,” said Zulf Ally, Chief of Administration Services in the Technical Services Department.

After NYCHA acquired the CNC lathe machine in late 2019 and the vertical lathe a few months later, the machinists have been able to significantly improve their turnaround time for completing part repairs, compared with the time it may take at an external facility. The machine technology also results in fewer mistakes than work done by hand, and NYCHA saves costs by having the devices reconditioned in-house in a shorter time frame, according to the machinists.

“What we’re doing now compared with what we did before has eliminated days’ worth of work and made it into hours,” Mr. Dombroski explained.

Mr. Ospedale, who recently retired after nearly 30 years at NYCHA and called the team “like family,” was also quick to point out the difference made by the new machinery while commending the work of the skilled machinists.

“Getting these machines saved us a lot of time and allowed them to do other work,” he said. “We can work professionally with the equipment that we have and get the jobs done in a timely manner.”

Most of all, the machinists said they are proud to do their part to provide vital services to NYCHA residents.

“It’s nice to know that our impact makes life easier for someone else,” Mr. Dombroski concluded.