The Ultrasonic Flow Meter That’s Transforming Fire Safety at NYCHA

Every few years, NYCHA must test the integrity of its fire suppression systems — the underground networks which deliver water from rooftop tanks to standpipes and sprinklers across its developments. These subterranean systems span multiple buildings and often lack sectional valves, making testing and leak isolation difficult.

But NYCHA’s Fire Safety Team, led by Senior Director Joe Terranova, is addressing that challenge — with the help of a powerful tool: the ultrasonic flow meter.

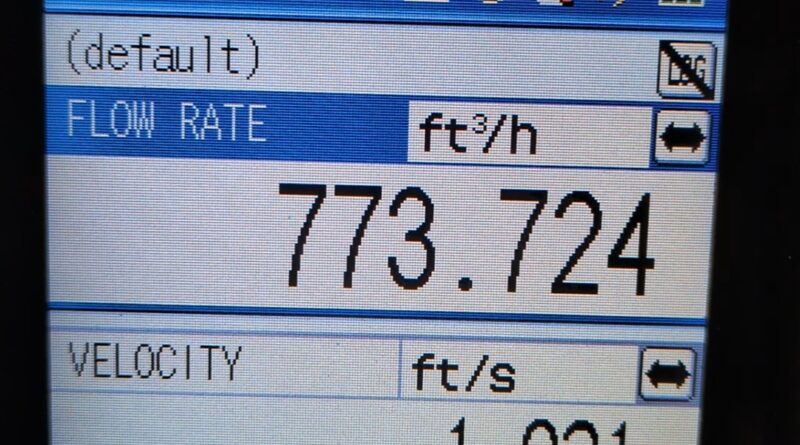

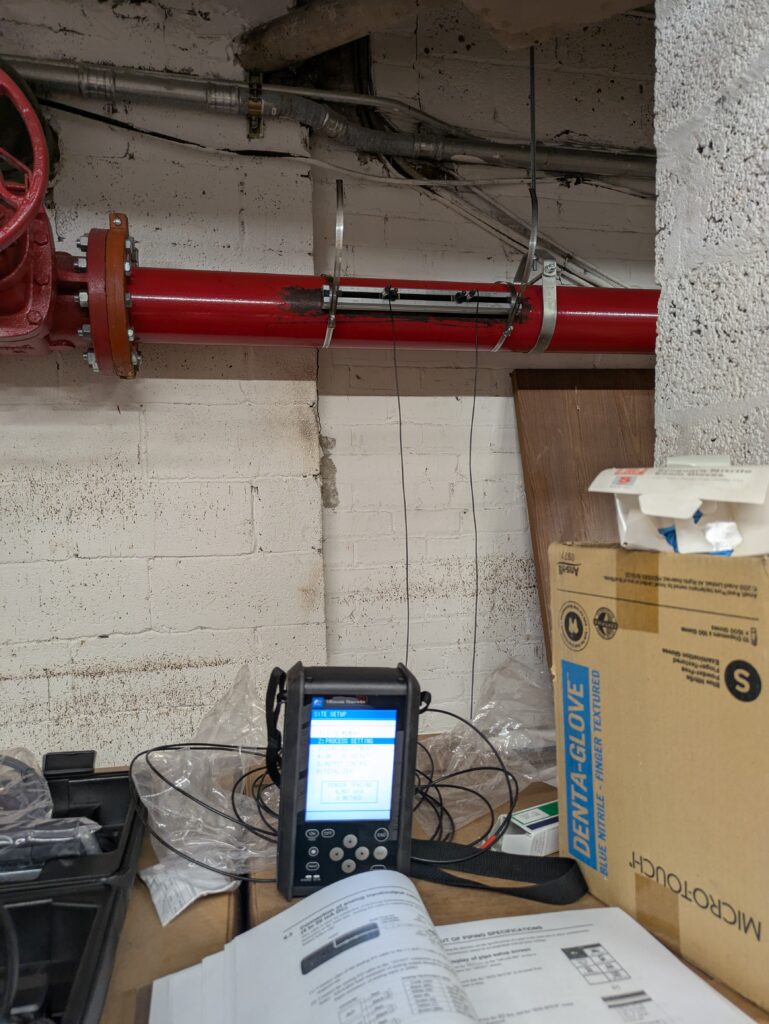

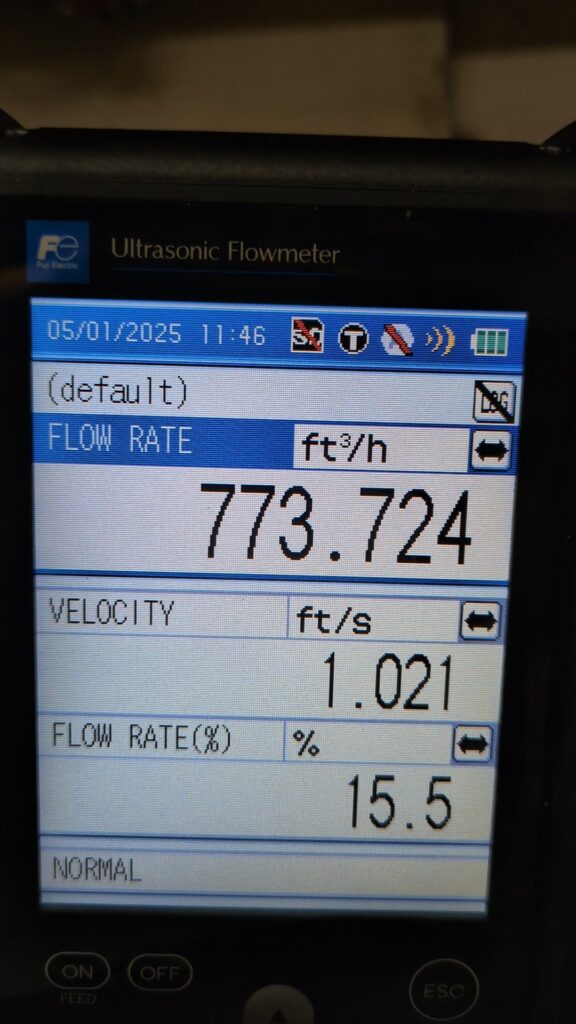

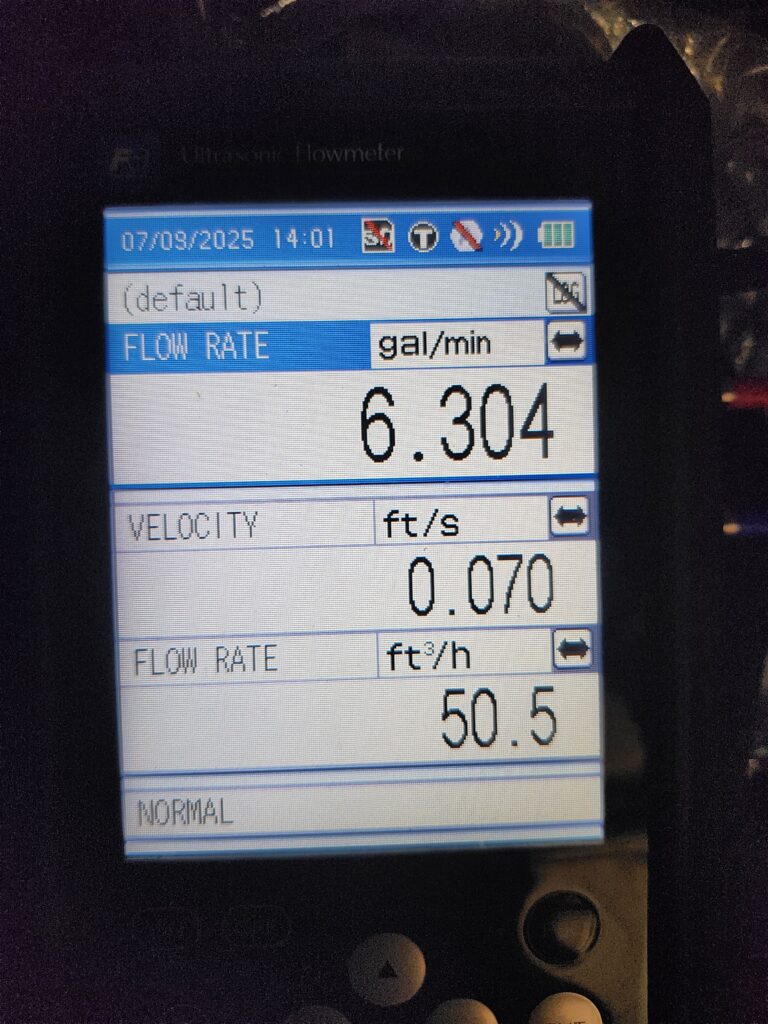

“It’s basically like Doppler radar,” Mr. Terranova explained. “We strap it to the outside of a pipe, and it tells us whether water is moving through it, in what direction, and at what rate (in gallons per minute).”

Fire Protection Specialist Bohdan Geba using the ultrasonic flow meter to help find a leak’s location.

It may sound simple, but this technology is making a major difference in tackling leaks, preventing the need for repairs, and improving fire safety for thousands of residents.

The Problem: Leaks You Can’t See

When pressure tests fail, it means there is a leak — somewhere. Above ground, finding the source of leaks is fairly straightforward. Underground is a different story. Pipes run four to fifteen feet below the surface, sometimes spanning thousands of feet. And fire protection water is supposed to be static — it should not be moving unless there’s a fire.

“You can’t see these leaks underground,” Mr. Terranova said. “And without sectional valves, you can’t test in segments. So if we lose pressure, we could be looking at a quarter mile or more of buried pipe to investigate.”

The Solution: Flow + Direction = Precision

The ultrasonic flow meter is a game-changer. It works by measuring the time difference of ultrasonic waves traveling through a pipe in both directions. Even the slightest variation reveals flow. With pipe diameter and velocity, leak rates can be calculated — and crucially, flow direction identified.

The ultrasonic flowmeter measures the time difference of ultrasonic waves traveling through a pipe in both directions.

Even the slightest variation reveals flow.

This allows Mr. Terranova’s team to “halve” the problem. “We find the midpoint of the suspected section and dig a test pit,” he said. “Then we attach the flow meter. If the water is moving, we know there’s a leak — and we know which direction it’s going. We keep ‘halving’ until we’ve narrowed it to a manageable section.” Often, just two or three test pits are enough to locate the leak.

Technology as a Force Multiplier

The impact of this tool goes beyond cost savings – it also facilitates speedier diagnostics and smarter work. And it’s part of a suite of modern tools — infrared cameras, video inspection cameras, and more — that are changing the way infrastructure is maintained in some of the city’s oldest housing stock.